Add to Cart

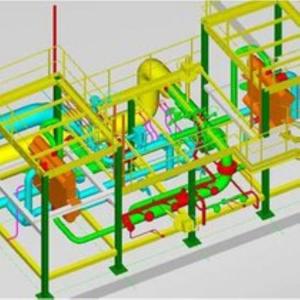

Two methods for recovering BOG

TCWY provides two proven technologies to help customers recover the BOG that is inevitably formed during periods when ultra low-temperature LNG is kept in storages

1) The BOG reliquefaction unit is a technology that relies on proven reverse nitrogen Brayton cycle to reliquefy BOG. Depending on the available pressure of the BOG, process schemes with one or two expanders may be used. The use of a nitrogen cycle allows a broad flexibility of operation, which is very well suited since BOG flow can highly variate over time

2) The second technology uses liquid nitrogen (LIN) as a cooling agent to recover BOG generated in LNG storages. Compared with a BOG reliquefaction unit, the technology offers the benefit of reduced initial investment cost, and is more suitable for moderate LNG storage capacity. It is typically the most adapted solution all along the small scale LNG chain.

Advantages of BOG Reliquefaction:

Recovers BOG all along the LNG transport chain, from well to end user, therefore ensuring “zero flaring” logistics

Maintains LNG fuel specification

Helps debottleneck LNG export terminals

Key figures:

Capacity: 30 to 500 tons per day

BOG unit consumption: 500 to 800 kilowatts per hour / ton

LIN consumption: 2 tons of LIN per ton of reliquefied BOG